Ambient measurements with Partector 2 & Pro

A growing number of customers are using the Partector 2 and Partector 2 Pro for continuous environmental monitoring

rather than

for shorter handheld exposure or occupational hygiene measurements. Performing such measurements and ensuring

high data quality is much more complex than making short indoor measurements.

There are six main issues to consider:

Use the right pump version

Avoid high temperature

Avoid high humidity (or worse, water entering the device)

Avoid particle losses in inlet

Avoid inlet clogging

Perform continuous quality control

The original version of the Partector 2 was meant for occasional workplace monitoring. The rotary vane pump in the original

Partector 2 was fine for that with a lifetime of ~4000 hours. For 24/7 monitoring, this is no good however, so if you

have an older Partector 2 with a rotary vane pump that you would like to use for ambient monitoring, get an upgrade to the

much more reliable new silent pump from us. Once you have the right pump version, we

recommend you follow the best practices described below to avoid producing bad or useless data, or in the worst

case, damaging your instrument.

Indoor measurement stations

Using the Partector 2 in a climate-controlled measurement station or container

avoids issues with temperature and humidity and is ideal.

Care must still be taken:

Ensure that the correct tubing is used. Especially,

conductive silicone tubing that is frequently seen is not suitable for the Partector 2. Make sure to check the

entire inlet flow path in the measurement station and that there is no black silicone tubing anywhere. If there is,

the high voltage in the instrument will increase rapidly, and within typically 4-8 weeks it will reach the maximal

value and a service action will become necessary.

Long inlet lines may lead to high losses of particles due to diffusion, the smaller

the particles the worse it gets. Ideally the inlet tubing leading to the Partector 2 at its 0.5 lpm flowrate should be no longer than 0.5m.

For details read the section on intercomparing results.

The Partector 2 and other aerosol instruments display warnings and errors if something

is wrong. Monitor the status of all your instruments regularly. For our devices, this is easily

done by using our IoT data cloud.

Outdoor ambient monitoring without controlled environment

The Partector 2 is miniature and needs very little power. It can run for a long time (weeks) on an external battery, or be powered with a small solar panel. It can also be mounted anywhere in a small protective enclosure due to its small size, and does not need a full-blown measurement station. This makes it very attractive for ambient measurements in locations which are normally not covered by monitoring networks.If you want to use the Partector for such measurements, it needs to be protected from high temperatures and humidities. As meteorological conditions may differ widely depending on location, it is impossible to give detailed instructions that will fit every location. However, you can apply the following general principles taking your local meteorological conditions into account.

Device temperature

The Partector 2 should not be operated below 0°C or above 40°C. Temperatures below 0°C will cause problems when charging the battery, reducing its lifetime. Temperatures above 40° will reduce the lifetime of multiple internal components and may cause early device failure.At a temperature of 50° or above, the Partector 2 will shut down its internal high voltage to protect the high voltage module from catastrophic failure at the high temperature; you will have no valid data when this happens!

Depending on your location, the design of the enclosure, and its exposure to sunlight, the temperature range from cold winter nights to sunny summer afternoon temperatures can be huge!

We recommend the following:

Avoid direct exposure of the enclosure to sunlight as much as possible, in particular at the hottest time of day (typically 3-5 PM).

If you use solar cells to power your setup, they can provide shadow to the enclosure.

Use a white enclosure to reduce heating by sunlight - the whiter the better. A light white paint finish reduces the temperature inside by up to 10°C.

Batteries that might be used with solar cells are also restricted to certain temperature ranges and especially charging below 0°C is not recommended or may be impossible.

Humidity inside the device

For long-term environmental monitoring, the Partector 2 should ideally be operated at relative humidities (RH) below about 50%. The Partector 2 is usually warmer than its surroundings due to waste heat. This reduces the internal RH below that of the outside air, but it may not be enough at high outdoor RH, for example when it is raining. Furthermore, as the sun rises, the air and surroundings heat up very quickly and the absolute humidity rises rapidly, while the Partector heats up more slowly in the shaded protective enclosure. In such situations, the RH in the device might be higher than in the ambient air.To protect itself against high RH, the Partector 2 will turn on a small heater at more than e.g. 80% RH (the default value depends on the firmware version). This heater is not very powerful, and we recommend to add some thermal insulation around the Partector 2 in the enclosure to keep its internal temperature higher relative to ambient. You should aim for at least about 5°C above ambient.

The relative humidity at which the heater activates can be changed. To change it, place a file called "commands.txt" in the root directory of the Partector 2's SD card, with a single line of text in it, for example like this to set the humidity setpoint to 50% (recommended for longterm ambient monitoring):

hA050!

Restart the Partector 2 to have it parse and execute the commands.txt file. When the internal humidity is higher than the setpoint, you will see a golden H in the title bar of the home screen, indicating that the heater is on.

High humidity will not damage the device unless it condenses and water accumulates inside the device. Issues with high humidity may cause warnings, visible on the device display, in the data file, or in the cloud dashboard if the device is connected to the cloud.

Why not to use a dryer

As explained above, we recommend to control relative humidity by temperature management of the device. Another standard technique in aerosol science is to use a dryer, such as a diffusion dryer or a Nafion dryer. We recommend not to use dryers with the Partector 2, and to rely on temperature management instead. There are real technical reasons to use such dryers for traditional instruments such as optical aerosol detectors, differential mobility analyzers (DMA) and condensation particle counters (CPC):- In optical instruments, light scattering increases with the 6th power of the particle diameter for particles smaller than the wavelength of the light. Even a small amount of hygroscopic growth of the particle will therefore result in a much larger signal, which is avoided by using the dryer.

- In DMAs, arcing of the high voltage may occur at high internal humidity. Because the system is large, heating is impractical. Furthermore, the DMA is usually coupled with the CPC, which also needs a dryer.

- In CPCs which often use hygroscopic Butanol as working fluid, water uptake by the Butanol changes (lowers) the counting efficiency of the device. The CPC has to operate at fixed temperatures for its counting efficiency to remain constant, so heating is no option here.

External dryers cause (often unknown) particle losses that would need to be accounted for, can be expensive, large and power hungry (as in the case of Nafion dryers) and can introduce further mechanisms of failure in the measurement chain.

Humidity inside the enclosure

The Partector 2 has an air outlet on its side. The enclosure may be cooler than the surrounding air (as explained above, mostly in the early morning), and then condensation might occur in the enclosure. We recommend to create an exhaust flow path to directly remove the sampled air from the enclosure.Some enclosures are airtight. In this case, you must create an exhaust flow path, as otherwise the sampled air has nowhere to go and the Partector's pump will not be able to maintain the normal sample flowrate.

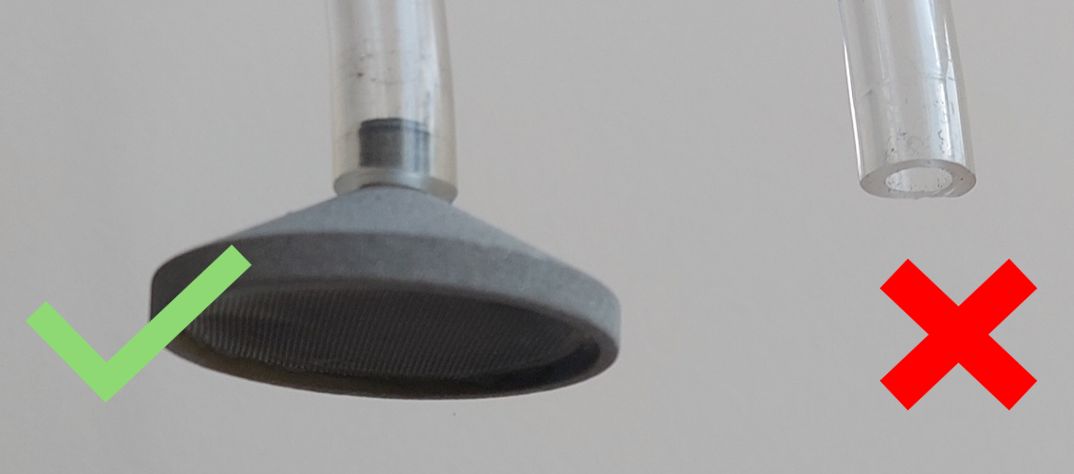

Inlet protection against insects and water

Make sure that your inlet design will protect against the aspiration of water by the Partector 2. For example, a simple tube even when oriented toward the ground is a really bad idea, as a water drop can form at its end when it is raining, which will be sucked into the device, potentially damaging the instrument. If enough water is sucked into the device and remains there long enough, you will damage the instrument beyond repair. The inlet diameter must be large enough that this cannot happen.Insects crawl everywhere, and like to hide in small holes. A fine mesh can protect the inlet. However, if the mesh is too fine, the inlet may become clogged over time, affecting the measurement results. This is an effect that is difficult or impossible to detect based on the system and measurement data and only regular inspection and cleaning helps. The image below shows a possible solution for the inlet, which will protect against both insects and rainwater. The conical piece is 3D-printed and a fine wire mesh (openings about 1mm x 1mm) is glued on the cone. Obviously, the side with the grid must be oriented towards the ground and must not be able to move in the wind. The conical shape is meant to increase the grid diameter, so clogging becomes practically impossible.

Losses due to the inlet

Once you have designed an inlet to protect against rain and insects, it will also remove some of the particles that you want to measure. The Partector 2 is calibrated without additional inlet, and any particle losses in the inlet need to be taken into account by the user. In general, try to keep the inlet flow path short to reduce diffusion losses of ultrafine particles.You may also use an impactor or a cyclone in your inlet system. Under normal conditions, this is not really necessary, but if you are measuring in an environment with many coarse particles, it could be sensible. Cyclones and impactors will add to the inlet losses, and may also clog over time, so make sure to clean your inlet system periodically.

Contamination

Over time, the insides of the Partector 2 become contaminated with dirt. This is unavoidable since dirt in the air is what is measured. When measuring in dirty environments, protection against coarse dust might increase the time between service intervals. The Partector 2 tracks a lot of internal parameters and will display warnings if the buildup of dirt has become critical.For 24/7 ambient monitoring, we recommend a service interval of 1 year.

For more information on maintenance and recalibration, check out our maintenance & calibration recommendations

Power

You can power your Partector 2 either via a large battery for a few weeks (e.g. for a measurement campaign), you can power it with a solar panel + battery solution, or via mains power. Commercial powerbanks often turn off after having charged a device connected to them, and don't turn on again. Look for a powerbank with an "always on" feature.As with the Partector's internal battery, most Li-Ion batteries are only specified for temperatures above 0°C. Using mains power solves such issues, but obviously leads to other limitations.

Example setup

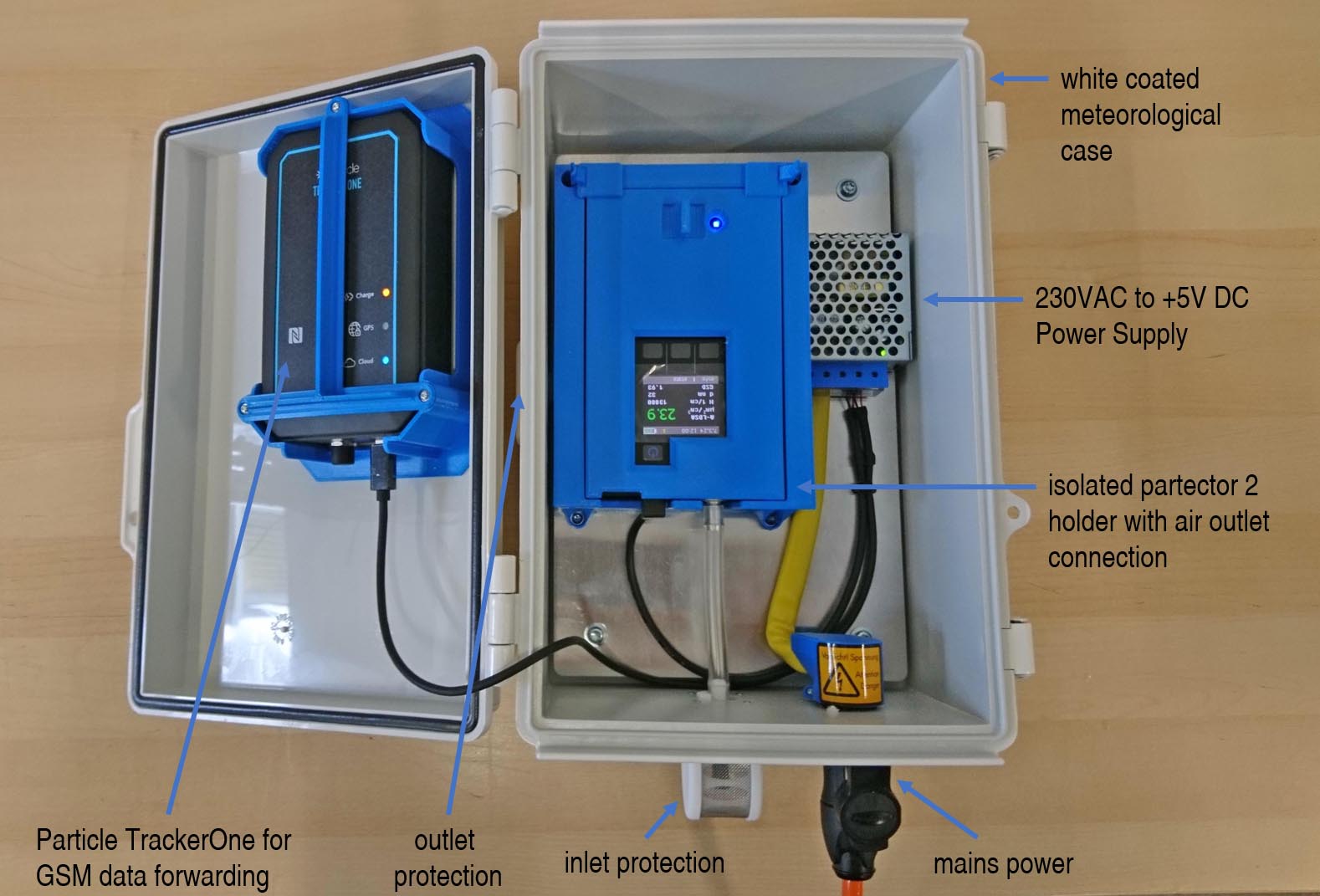

The picture below shows an example setup that we have used successfully for ambient monitoring in Switzerland. The following details are noteworthy:- White case to prevent overheating in the sun

- Some thermal isolation around the Partector 2 to keep it above 0° at subzero ambient temperatures, and to keep the Partector 2 a bit warmer than the ambient temperature even when the ambient temperature is rising quickly (e.g. in the morning after sunrise). Without this, condensing conditions can be produced in the device!

- Only a short piece of tubing (~10cm) between inlet of the case and the Partector 2 to minimize particle losses

- Air inlet protected by a wire mesh, and oriented towards the ground to prevent rainwater from entering

- Air outlet (not visible) also protected by a wire mesh, and oriented towards the ground.

- Data transmission to monitor the device online at all times.

Intercomparing measurement results

When comparing data of different instruments that measure ultrafine particles, one nearly always finds discrepancies

between different types of instruments. Reasons for this are:

Reference instruments

The size range of different instruments is often different. The

most common example for this is: Different condensation particle counters (CPC)

have a different lower diameter cutoff (d50, e.g. @ 7nm; 10nm).

Scanning mobility particle sizers (SMPS) can also be set to

different size ranges.

Condensation particle counters often have a limited

concentration range (e.g. up to 100'000 pt/cc) and cannot see higher concentrations, whereas the Partector 2 does.

If you are measuring close to a particle source (road, airport), you might see such high concentrations which

will seem to disagree with the CPC, because it cannot measure the high concentrations.

Just like the Partector 2, reference instruments also need regular

service/maintenance. Make sure service intervals are complied with, and regularly check for warnings or errors of

reference instruments.

Inlet losses

When comparing instruments that use different inlets, losses in the respective

inlet systems must be accounted for. Especially for the smallest particles, losses by diffusion can be relevant.

An example: if you sample air for the Partector 2 with a 0.5m long tube, about 10% of the 10nm particles will be

lost by diffusion.

Current standards

For particle number measurement: CEN/TS 16976:2016 specifies a 7nm d50 cutoff.

For particle size distribution measurement: CEN/TS 17434:2020 specifies a 10-800nm measurement.

Both standards specify how particles must be sampled.

Be aware: The CEN-compliant TSI SMPS will apply a correction for the inlet losses. If you connect a Partector 2 at the same inlet system,

it does not know about these losses and will show lower concentrations than the reference.

A recent paper by Asbach et. al. compares a Partector 2 Pro with a CEN-compliant SMPS system. They corrected the Partector 2

data for the correction factor applied by the SMPS system.

Multiple Partector 2 versions

The Partector 2 is available in a standard version where an assumption

on the particle size distribution is made (lognormal, geometric standard deviation 1.9) to calculate particle diameter

and particle number. The standard version reports LDSA, average particle diameter, and particle number concentration.

Since 2022, it is also available as Partector 2 Pro, which makes no assumption

on the particle size distribution, and which reports a particle size distribution (8 channels from 10-300nm). The pro version

can also run in standard mode, but not vice versa. The two versions will produce slightly different results.

We continuously improve our devices. To make the most of your

instrument, keep it serviced regularly where any improvements to hardware/software or calibration procedures will

be applied.

Further information

For further information please also read our FAQ with some more questions and answers

or browse through our list of publications with articles from other scientists.

For any further questions, contact us under:

info@naneos.ch